CAPABILITIES

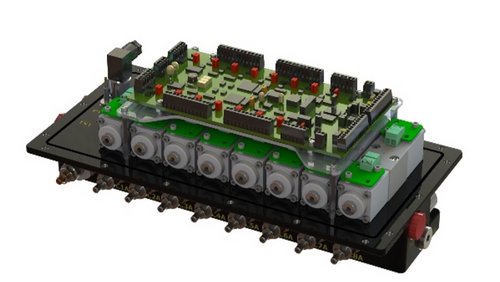

Wandfluh Subsea, offer a full turnkey solution for Hydraulic and electronic bespoke builds and assemblies, covering:

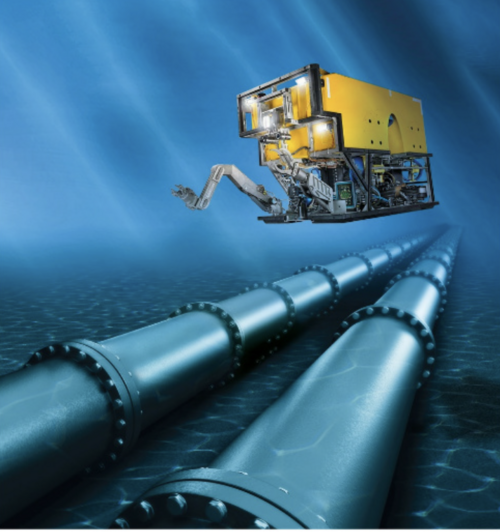

Wandfluh UK solutions offer the “Plug and Play” approach when fitted to our customers machines, as we take

pride in enabling Remotely Operated Vehicles (ROV), operating at depths of 4,000–6,000 meters below sea

level. Our cutting- edge products have been instrumental in controlling Manipulators Arms / Thrusters plus Tooling

Equipment for years, ensuring seamless operations in the most challenging underwater environments.

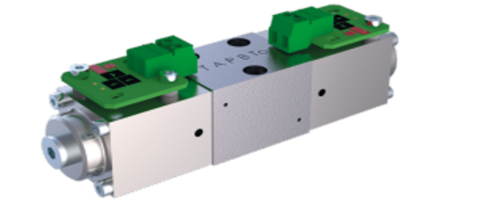

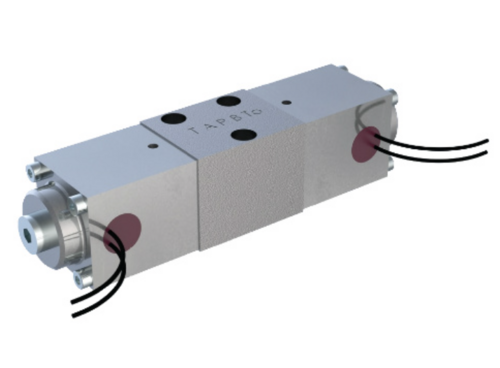

Wandfluh Valves are engineered to withstand ocean pressures when operating at typical depths of 4000-6000 m, offering durability and reliability, ensuring you stay on target for the contracts that you have won. Wandfluh products have established a Worldwide reputation over many decades, of providing the right valves for the demanding applications in subsea.

Here at Wandfluh UK, we take pride in our expertise in our subsea solutions. Through many years of working and listening to our customers, we work together to define the concept. Design, manufacture, supplying the complete assembly, fully tested, offering a seamless integration into their machines.

"Wandfluh UK solutions offer the “Plug and Play” approach when fitted to our customers machines, as we take pride in enabling Remotely Operated Vehicles (ROV), operating at depths of 4,000–6,000 meters below sea level. Our cutting-edge products have been instrumental in controlling Manipulators Arms / Thrusters plus Tooling Equipment for years, ensuring seamless operations in the most challenging underwater environments.

Tether management systems (TMS) are used for storing and deploying an ROV to operate at depth independently of support vessels motion. TMS operate subsea and have a range of lengths of tether to allow the ROV to operate at a greater working radius. TMS systems are submerged in water, meaning all hydraulic and electronic components must be designed to operate at depth in harsh working environments. Trust in Wandfluh products to deliver for these specialist environments.

Wide range of flows available in number of Cetop interfaces, allowing optimal performance from smallest space envelope.

Remotely operated vehicles (ROV) are used for a number of subsea operations, from observation to work-class ROV’s providing deepwater intervention at depths of up to 6000m in hostile and challenging environments. Reliability is key to an ROV, and Wandfluh has built up their reputation over the decades of being a market leader for control valves used on ROV’s and subsea vehicles through high quality Swiss product, innovation and unparalleled support and service. Flexibility in design and components means you can trust Wandfluh to offer the best solution for your needs.

Miniature valves offering the smallest space envelope required for hydraulic functions.

Wandfluh Subsea, offer a full turnkey solution for Hydraulic and electronic bespoke builds and assemblies, covering:

Wandfluh works in conjunction with clients to design and develop the best solution for application. From initial enquiry and circuit requirements to a final design fully integrated onto equipment or vehicle.

Wandfluh Subsea, offer a full turnkey solution for Hydraulic and electronic bespoke builds and assemblies, covering: