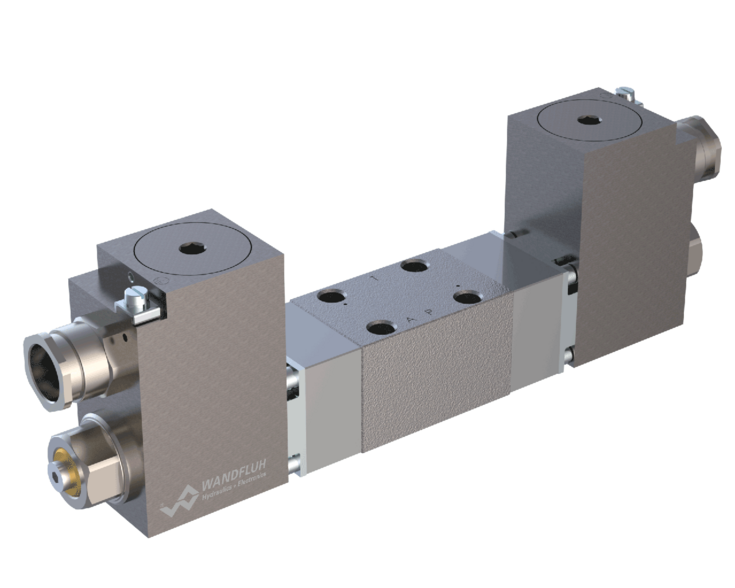

Detented poppet valve for explosion hazard area AExd3206rr

Wandfluh has extended the proven flange poppet valves for the modular valve assembly with an execution for use in explosion hazard environments. The valve is switched with an electrical impulse and remains in this position until the solenoid on the opposite side switches back the valve into the initial position. By this, the solenoids do not have to be continuously actuated, which saves energy and does not change the switching position in case of a power failure.

The valve can switch a volume flow of 40 l/min at up to 350 bar. By the seat tight closing of the P-line or T-line, the working connection A does not have any internal leakage. The valve solenoid coils have a large number of different explosion protection certificates: ATEX, IECEx, UL/CSA, EAC, Nepsi, MA, Inmetro and Australia. Thus, the valve can be used worldwide in installations up to explosion protection zone 1 or 21 respectively as well as for mining.

The solenoid coil, the armature tube and other parts on the valve are very well protected against corrosion by their zinc/nickel coating (1000 h in salt spray test). The direct operated valve of nominal size NG6 is available as a 3/2-way function with the designation AExd3206rr. The applications can be found where the selected switching position must be retained even in the case of a power failure or a cable break and at the same time, no increase or decrease in pressure can be tolerated at the working connection.

Further details can be found in data sheet <link https: www.wandfluh.ch en product-liste product-single aexd3206rr external-link-new-window external link in new>1.11-3146.